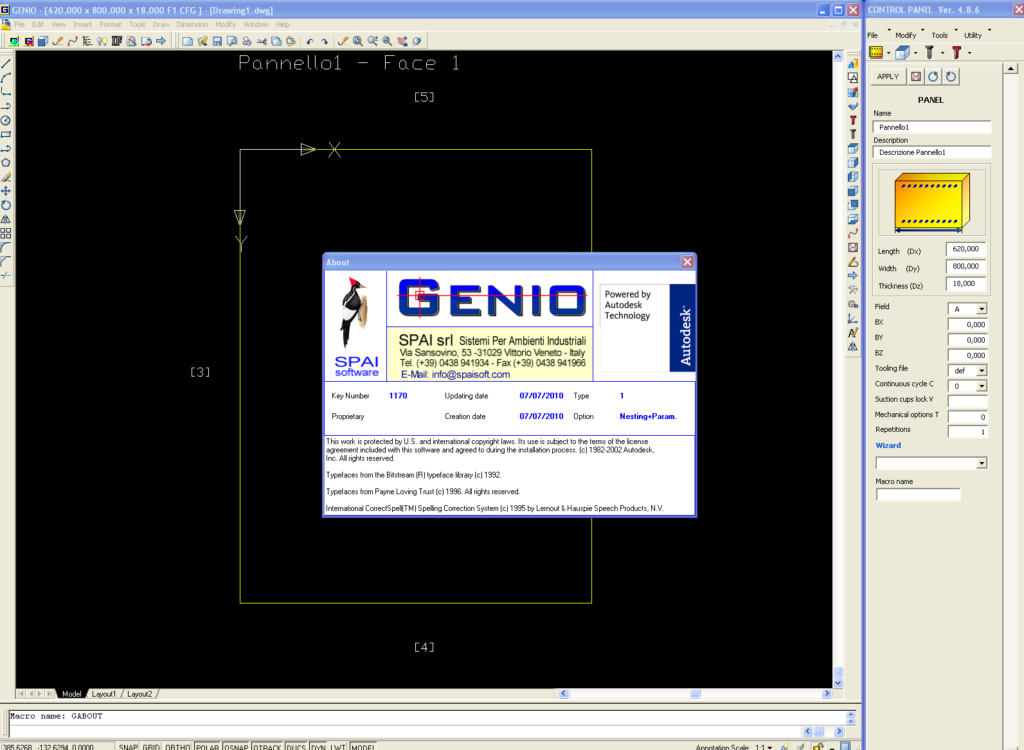

Genio CAD CAM Test With Eutron Smartkey Dongle Emulator Clone

Genio

Computer aided design/CAM programming incorporated in AutoCad© for parametric programming of exhausting, steering and edge-banding workcenters

Outline

- Genio is an effective CAD/CAM framework in view of AutoCad© 2004 OEM enviroment (the AutoCad© motor is circulated inside the application)

- The administrator can draw or import geometries and afterward apply in a quick and simple way all machinings required to achieve the ideal outcome

- Machinings can be customized in parametric frame by utilizing the Genio Macro Programming Language, this permits clients to fabricate capable parametric libraries customized for their own segments

- Genio permits the remote programming of a few machines from a solitary position

- Genio is the correct decision for the organization that takes a gander at what’s to come

Essential FEATURES

- Computer aided design environment with AutoCad® 2002/2004 motor and functionalities

- Import of instruments and suction containers information from the machine control. Apparatus definition

- Administration of both geometries and machinings with a few CAD

- capacities (erase, duplicate, glue, move, pivot, and so on..)

- Vertical, flat or inclining drillings: single gaps, gap obstructions or

- gap arrangement on given geometries

- Vertical, flat or inclining routings, on any processable geometry

- Programming of millings lead In/Out, Start/End focuses, beginning stage, apparatus counterbalance, speeds, and so forth…

- Straight or concentric pocketings on any-shape shut strong geometries with complete section and programmed acknowledgment of the inward islands (gaps) of pocketings

- Cam utility for inward corner cleaning of any processable profile (work valuable for entryways)

- Administration of machinings with conic devices on shut geometries (3D inscriptions)

- Meaning of client working planes (inclining planes)

- Parametric Macro programming with Excel-like full scale dialect (parametric Macro library provided with the product)

- Machinings dimensioning and reports spared as Excel spreadsheet or as content record

- Programmed check for projects plausibility

- Representation of machinings with 3D strong view and recreation

- Content and images, from genuine sort text styles, as workable geometries

- Association with digitizer for focuses obtaining on a profile

- Programmed era of machinings successions from a drawing

- as indicated by a predefined machining profiles (Genio wizard)

- Trade/import of projects to/from CNC Working Center.

Settling

- The settling procedure permits to cut a rundown of any-shape boards

- (pieces) beginning from an arrangement of any-shape given materials (sheets)

- with the question of limit the aggregate waste. The Genio settling utility backings the accompanying elements:

- Sheet chronicle programming and utilized material emptying

- Piece list programming with bits of various materials (multi-work programming)

- Freestyle, rectangular and guillotine cuts nestings

Pieces labeling

- Supersede cutting examples physically

- Printable cutting examples

- Generation and prerequisites reports

- Names Editor

- Names imprinting on committed printer or on Windows printer

- Yield of advanced CNC settling programs.

RASTER TO VECTOR

- The Raster to Vector utility permits to import spared raster pictures documents as Autocad drawings that can prepared to create the journalist CNC code.

- The utility backings the accompanying components:

- Import of pictures put away in documents with a few illustrations designs bolstered (bitmap, jpeg, tif, and so forth..) as workable drawings

- Choice of the addition point, turn and size of drawings onto the screen

- Vectoralization on centerlines or on blueprints with programmed identification of substances, for example, circular segments and lines.

PARAMETRIC GEOMETRIES PROGRAMMING

- The Parametric programming utility permits to apply parametric limitations to existing geometries with the question make parametric the reporter tooling ways. The utility backings the accompanying components:

- Parametrization of drawings with customized imperatives for existing polylines

- Usage of worldwide or characterized neighborhood factors accessible inside equations

- Programmed programming of preset limitations (settled separations from board edges, focusing, reflecting, and so forth..)

- Setting of digression imperatives between two continuous realistic elements (Arc-to-circular segment)

- Worked in parametric library.

if need solution Please contact us.