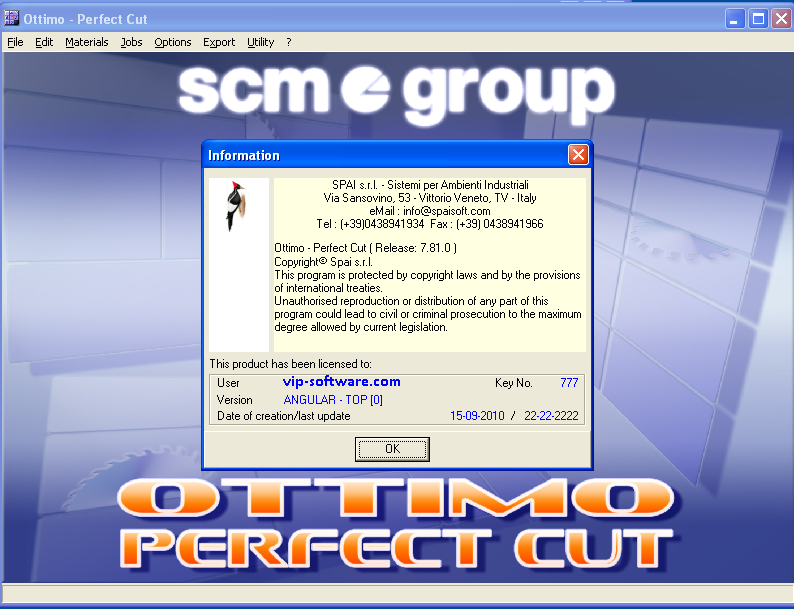

Ottimo Perfect Cut 7.100 Test With Smartkey Eutron Dongle Emulator / Clone / Crack

OTTIMO PERFECT CUT

Cutting Optimization programming

Outline

What is

Ottimo-Perfect Cut is a cutting improvement programming.

for single sharp edge and rakish bar saws with a few components,

for example, materials file administration, pieces chronicle administration,

single-occupation and multi-work (cutting rundown with bits of a few materials) streamlining,

expected machining time and costs calculation, machine code era, creation reports, boards marking, 3D reenactment.

Where is

Ottimo-Perfect Cut is introduced in a PC with Windows® O.S. in the production line or in the workplace,

can be associated with an Ethernet connect with the organization programming and with the Panel saw programming interface.

Why

Ottimo-Perfect Cut permits to acquire an upgraded. arrangement of cutting example beginning from a cutting rundown,

a material rundown and a machine design. By adjust the design parameters you can acquire the arrangement as required,

with least waste or least machining time. Finish generation reports are accessible.

Enhanced projects can be traded effortlessly to the board saw.

In addition the streamlining agent indicates report with evaluated.

times and expenses and yield altered marks for acquired pieces and off-cuts.

Fundamental FEATURES

Materials Database (up to 3.000 unique sheets)

Sheets arrangement for material sort

Grain and trims data for every sort of material

Programmed utilized sheets emptying and off-cuts reuse

Pieces Database (up to 10.000 distinct pieces)

Basic occupation programming to streamline cutting records with boards of a similar material.

Standard parameters can be altered for every occupation so as to acquire the best outcome.

A few sheets and off-slices arrangements can be chosen to cut pieces

Creation information, squander and machining time are appeared to check promptly for result

Programmed filling of cutting examples with by utilizing a filling list.

Report with enhancement general measurements.

(straight meters, surfaces range, volumes, squander, etc…)

Materials, boards and strips report.

Graphical lay-outs of cutting examples with pieces and waste dimensioning.

All reports can be spared as PDF records.

The manual editorial manager permits to embed, erase, move and pivot pieces;

to embed, erase and move head-cuts.

Points of interest are appeared for each chosen board or waste in the example.

The pieces can be embedded from the occupation list,

from the piece chronicle or as another piece.

Insights of the adjusted example are consequently upgraded.

MULTI-JOB PROGRAMMING

The multi-work programming permits to upgrade cutting record.

(up to 10.000 lines of pieces) with boards of a few materials.

The first cutting rundown is detonated in a few basic rundown with bits of a similar material.

Synopsis report of the total employment.

Work IMPORT, COSTS, MACHINE CODE GENERATION.

Work import from an arranged conten.

document or from Excel ® (EasyCut or EasyCut Plus required).

Fare of machine projects spared onto floppy plates,

nearby or Ethernet ways.

Fare of a rundown of program with a few sort of materials (LLT arrange).

Send out (part) of a solitary occupation up to three distinctive board saws.

Assessed machine time and expenses.

PIECES LABELING

Marks can be printed each and every piece or by book or by heap of pieces.

Marks can be printed disconnected in the windows printer or on-line in the.

name printer at the saw via programmed sending name information for the pieces.

Names can be printed for both pieces and off-cuts of the occupation.

Graphical Label editorial manager with content,

standardized tag, lines, drawings, to redo the name layouts.

3D SIMULATOR AND PIECES UNLOADING REPORTS.

Virtual machining 3D recreation of the occupation.

Perspective of expected machining time.

Perspective of the dynamic cutting example with data on the machining cycles

Arrangement of dimensional parameters for the pieces emptying process

Stacks report for every piece.

Sequential report of stacks organization with graphical lay-out

Report of utilized beds with graphical lay-out.