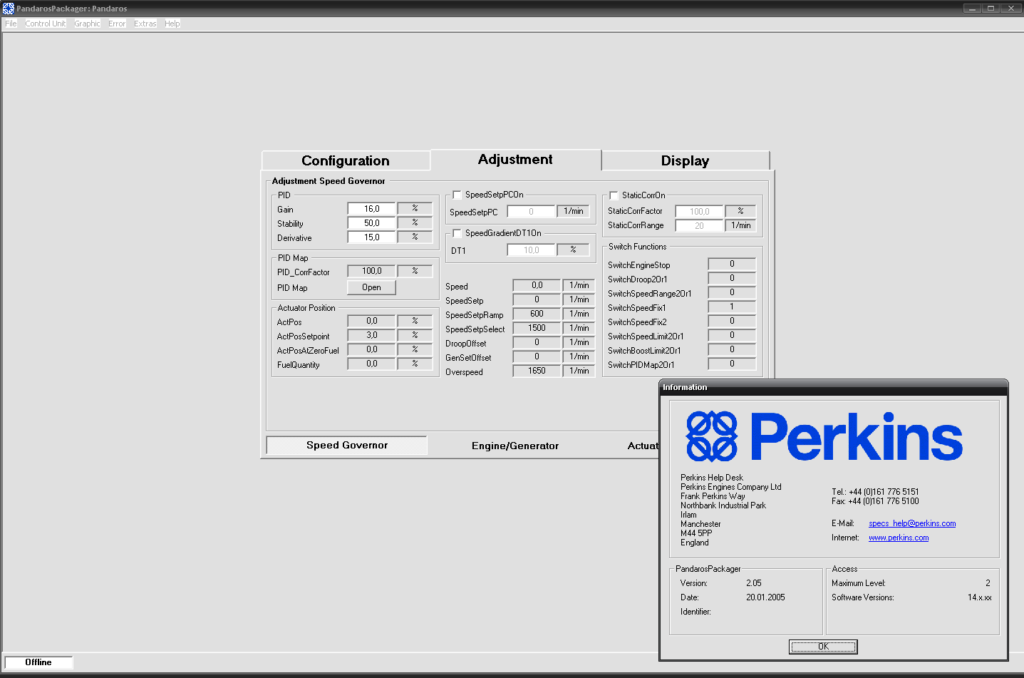

Perkins Pandaros Packager Test with Hardlock Dongle Emulator / Clone

Perkins Pandaros

Description of system

The digital control unit is the core of the approach.

There’s a 16 bit microprocessor in the manipulate unit.The processor operates the software

which controlsthe process.

The software which controls the systemis saved in a FLASH-EPROM section of the memory.

The manipulate unit compares the precise engine speedthat is measur ed with the aid of the

magnetic pickup on theflywheel with the preferred speed of the engine.

Thecontrol unit helps to pressure the actuator and the inputof the fuel to the engine so that the

genuine enginespeed matches the desired engine velocity.

Enhance stress for the engine is measured and usedin order to

control fueling for surest performanceand minimal smoke.

Extra inputs are to be had for the measurementof the following information:

Engine temperature

Fueling manipulate in opposition to engine temperature

Connection of additional automated load sharing

Synchronizing apparatus A pc application with exact interface cable is used for preliminary

atmosphere of the parameters for the governor andoptimizing the process and for locating faults.

A CAN bus is on hand for connecting to digitalsharing of masses and synchronizing equipment

andfuture monitoring of the procedure.If a sensor or the actuator is at fault, an alarm isissued

and there will probably be an engine shutdown. Internalerrors get detected also and the

blunders will be storedas all different failures. All failures will also be pink with anexternal pc.

To optimize the dynamics for every operating factor,the parameters for the PID are corrected.

Theparameters rely on the engine speed, the enginetemperature and load on the engine through stabilitymaps.

Proportional achieve values, indispensable acquire valuesand acquire values for

the spinoff can also be modifiedfrom the carrier software.

An factor for the overspeed is programmed into thegovernor.

If this point is handed, the governor willissue an alarm and the actuator will completely pull to thestop position.

if need solution please contact us.